Important Things To Know About Combustion Inspection Of Gas Turbines

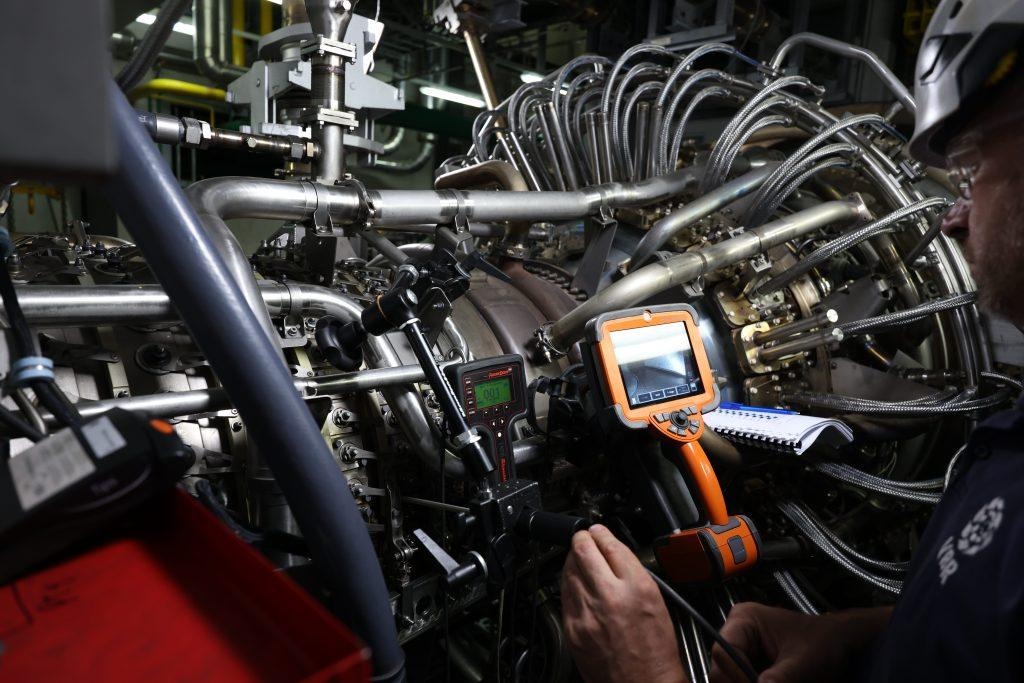

One methodical checkup of gas turbines is combustion inspection, or CI. Because the chamber is vital for energy conversion, it plays a critical role in guaranteeing safe and effective operations.

Technicians evaluate the operation and integrity of parts such as liners, flame tubes, and fuel injectors. These components are necessary to minimize emissions and achieve maximum combustion efficiency.

Frequent CIs are essential to spot possible flaws before they become more serious. Ones that could result in expensive repairs or lost productivity.

Operators may make sure the gas turbine runs smoothly and conforms with environmental laws. Of course, by carrying out these kinds of checkups.

Key Components Inspected

Know that turbine inspection services examine several important elements. Among them are:

- Fuel Nozzles: For uneven spray patterns, blockage, or breaking.

- Cans and End Caps: Inspected for material deterioration, blistering, cracks, and hotspots.

- Transition Pieces, or TPs: As they direct hot gas to the equipment, they are examined for deformation and cracks.

- Crossfire Tubes: Integrity is checked.

- Flame detector and igniter assemblies: They were examined for correct operation. Vital for guaranteeing the presence and stability of the flame. Be aware that malfunctioning detectors might result in dangerous situations.

- Casing: Checked for distortion, hotspots, and leaks.

- First-stage turbine nozzles and buckets: removed or visually examined for damage using a borescope.

- Fuel injectors: Crucial for supplying the proper quantity of fuel to the ignition chamber. Their state affects emissions and efficiency.

- Liners: These parts must be inspected for wear or damage because they shield the flame from the casing.

- Leakage and Seals: To stop extraneous substances from entering the fire chamber and interfering with ignition. It’s essential to check the seals surrounding it for leaks.

Cautionary Signs

Effective maintenance depends on spotting early warning indicators of possible combustion-related problems. Typical indications consist of:

- Increased Emissions: An increase in emissions may indicate issues with ignition.

- Temperature Irregularities: Inefficient ignition or component wear may be indicated by abnormal temperature measurements in the fire chamber.

- Visual Indicators: Components may exhibit cracking, discoloration, or other irregularities during inspections.

Early detection of these indicators lowers the likelihood of costly repairs. Also, operational disruptions by enabling prompt intervention.

Common Root Causes

These can have several underlying reasons, such as:

- Fuel Quality: Efficiency may be impacted by variations in fuel requirements. Gasoline injectors as well as fire chambers may develop deposits as a result of low-quality gasoline. See https://netl.doe.gov/sites/default/files/gas-turbine-handbook/3-1.pdf for further reading.

- Airflow Restrictions: Inefficient burning might result from insufficient or uneven airflow caused by obstructions or broken fans.

- Mechanical Wear: High pressures and temperatures can cause wear on components, which can affect overall performance.

Implementing successful initiatives and guaranteeing operational stability requires an understanding of these underlying reasons.

Purpose and Benefits

- Safety & Efficiency: Maintains peak performance by spotting problems before they become serious.

- Cost Reduction: Prevents expensive unplanned downtime and catastrophic failures.

- Extends Life: By addressing wear in important locations, downstream components have a longer lifespan.

- Condition-Based Maintenance: Future repairs, like recoating or replacing worn parts, are guided by findings.

Types and Levels of Inspections

- CI: A brief outage that concentrates on the components of the combustor.

- HGPI: This involves removing the shell to do a thorough inspection of the nozzles as well as buckets, in addition to the CI scope.

- VBI: This non-invasive method looks for concealed deterioration using borescopes.

Diagnosis and Research

Inspection results are diagnosed using a combination of diagnostic techniques and visual evaluations. Technicians may use methods like:

- Borescope Inspections: Permit interior visual inspections of components without disassembling them.

- Gas analyzers: To assess efficiency, measure emissions, and various byproducts.

- Vibration Analysis: Look for unusual vibrations that can point to problems with connected systems or components.

By using these diagnostic techniques, operators can easily identify and troubleshoot problems.

Corrective and Mitigation Measures

Several tactics can be implemented after problems are found during a CI:

- Component Replacement: It may be necessary to replace damaged or ineffective parts, such as fuel injectors, as well as liners.

- Tuning and Calibration: Improving fire efficiency can be achieved by modifying the fuel-air mixture. While also being sure that systems are properly calibrated.

- Preventive Maintenance: Putting in place a routine for preventive maintenance helps lessen the chance of future combustion-related problems.

Gas turbines can sustain high performance and dependability throughout their operational lives by adopting a proactive mitigation strategy.

Effects on Risk and Plant Performance

The entire operation of the facility and the associated dangers are greatly affected by combustion inspection. Efficient ignition improves operating economics by reducing pollutants and increasing energy output – read more for added info. Know that ignoring combustion checks may lead to decreased productivity, more downtime, and non-compliance with regulations.

Additionally, maintaining efficient ignition processes reduces the risk of operational issues. Such as explosions or unscheduled shutdowns, protecting both people and equipment. The efficient and secure functioning of gas turbines in a power generation facility depends on a thorough combustion inspection process.